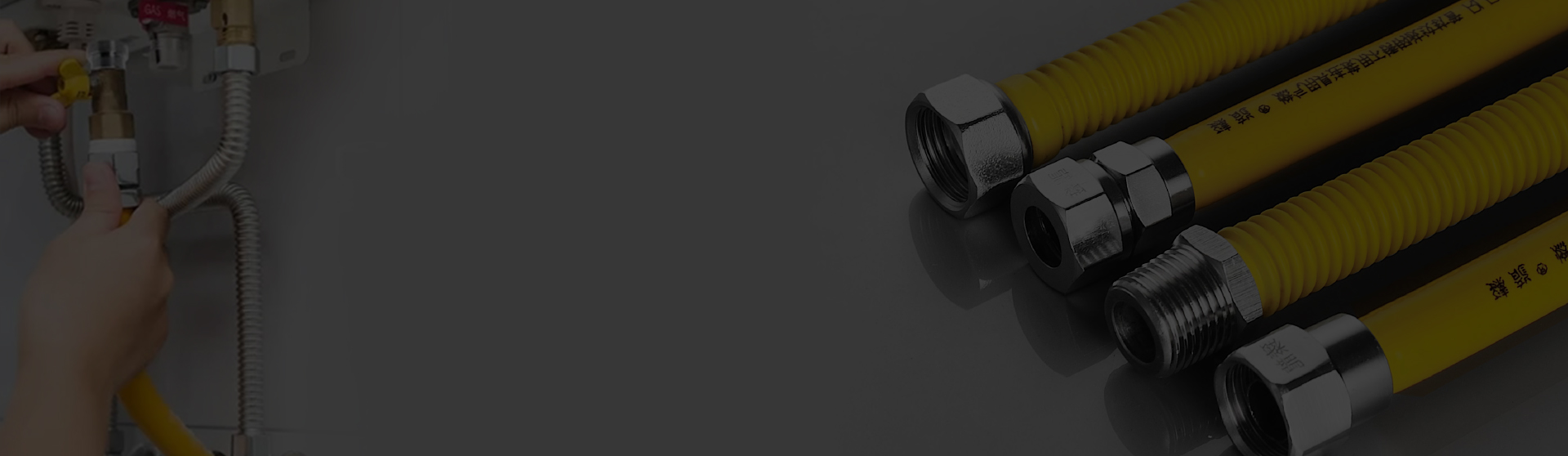

Stainless steel corrugated hoses are an important pipe connection and protection material, widely used in various industries, especially in chemical, petroleum, metallurgy, construction, shipbuilding, and automotive fields, playing an irreplaceable role. This type of hose possesses excellent mechanical properties, corrosion resistance, and high-temperature resistance, thus finding wide application in many situations requiring complex working environments.

1. What is a Stainless Steel Corrugated Hose ?

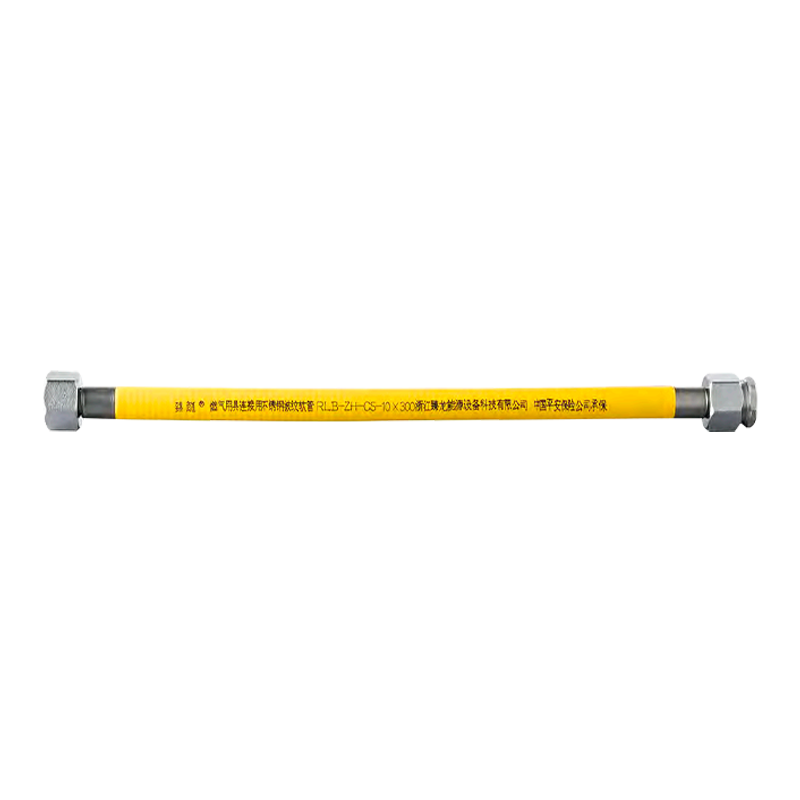

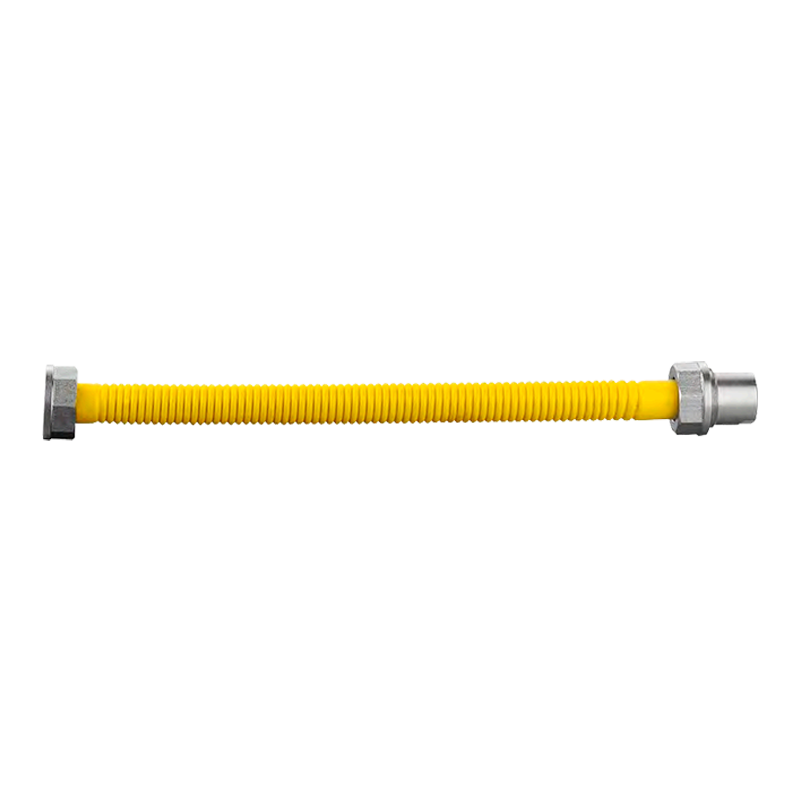

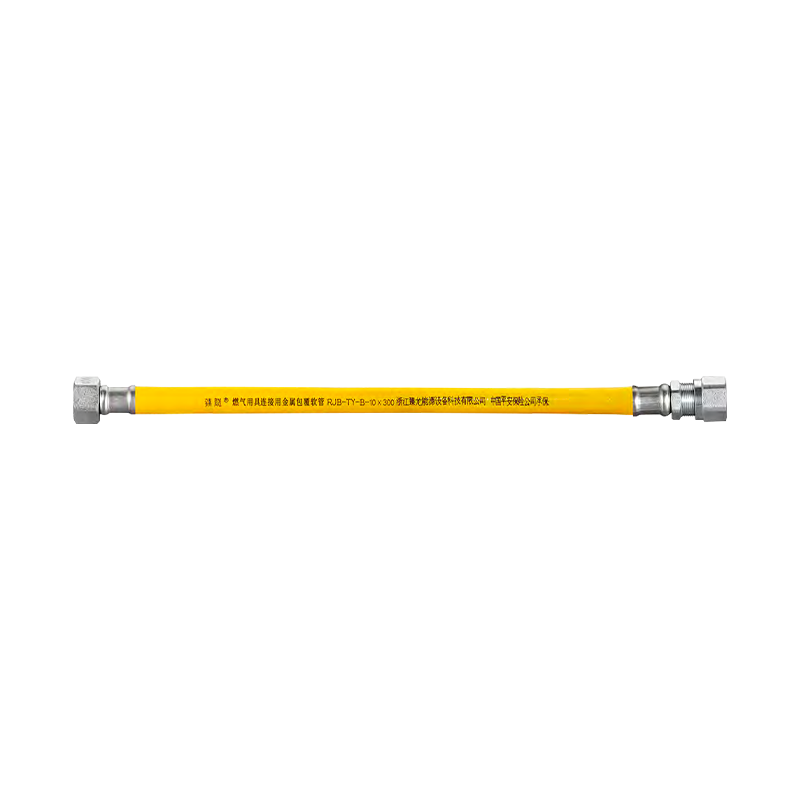

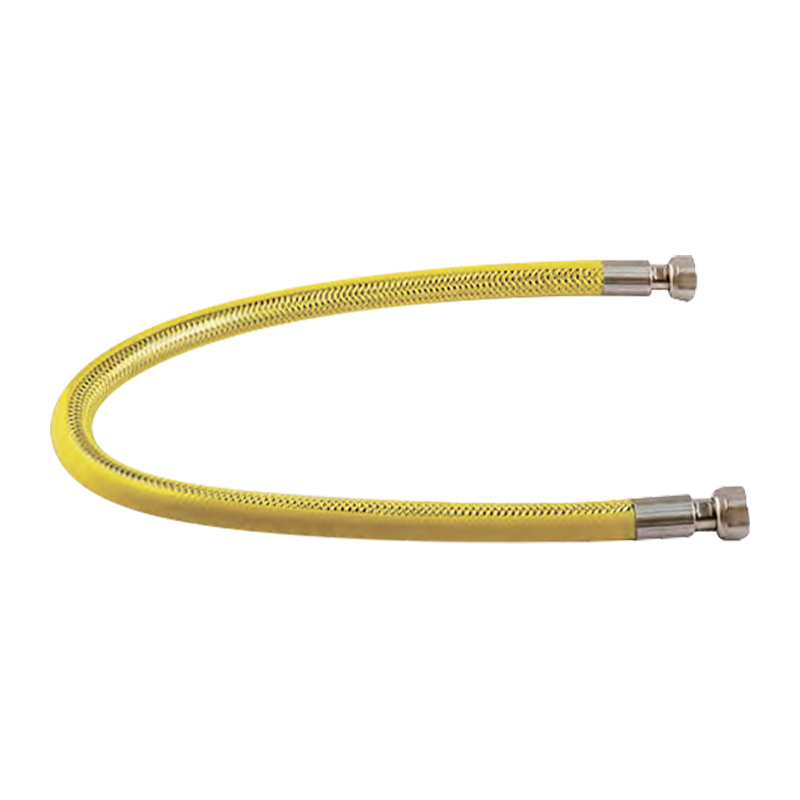

A stainless steel corrugated hose is a flexible pipe made of stainless steel with a corrugated surface structure. The corrugated design gives the hose good flexibility and extensibility, allowing it to adapt to various pressure, temperature changes, and mechanical vibrations in different working environments.

The main components of a stainless steel corrugated hose include the following:

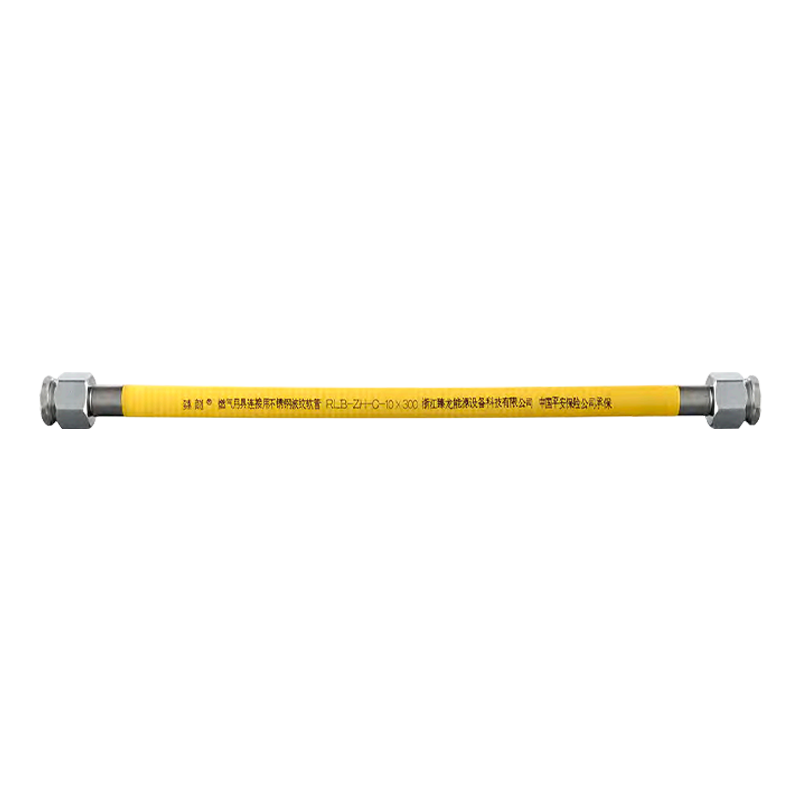

Corrugated Body: This is the core part of the stainless steel corrugated hose, usually made of stainless steel (such as 304, 316, etc.). The corrugated design gives the hose excellent extensibility, enabling it to cope with various pipe displacements, vibrations, and pressure changes.

Inner Liner: Some stainless steel corrugated hoses have an inner lining (such as PTFE, rubber, etc.) to further enhance the hose's sealing performance and corrosion resistance.

Outer Sheath: To increase the wear resistance and impact resistance of stainless steel corrugated hoses, some hoses also have an outer protective layer. This protective layer is generally made of braided stainless steel wire mesh or other metal materials, effectively protecting the corrugated pipe body from physical damage.

Connectors and Fittings: Stainless steel corrugated hoses are usually equipped with various connectors, clamps, and flanges for easy connection to other piping systems, ensuring the system's sealing and stability.

2. Advantages of Stainless Steel Corrugated Hoses

Stainless steel corrugated hoses perform excellently in many industrial applications due to their unique structural design and material advantages.

The following are their main advantages:

High Flexibility and Adaptability

Stainless steel corrugated hoses have very high flexibility, maintaining a stable working state even when the piping system experiences displacement, vibration, or changes in mechanical stress. This makes them ideal for connecting equipment that requires frequent displacement or vibration, such as engines and pumps.

High and Low Temperature Resistance

Stainless steel corrugated hoses exhibit excellent temperature resistance, enabling them to operate continuously in both high and low temperature environments. Different types of stainless steel are available to meet varying temperature requirements, with some models capable of withstanding operating temperatures up to 600°C.

Strong Corrosion Resistance

Due to the use of stainless steel, corrugated hoses possess exceptional corrosion resistance, maintaining stability even in chemically corrosive environments for extended periods. Therefore, they are widely used in the chemical, oil, and natural gas industries.

Good Pressure Resistance

Stainless steel corrugated hoses can withstand high internal and external pressures, making them suitable for use in high-pressure environments. Their corrugated structure effectively mitigates external impacts, preventing pipe rupture or leakage.

Vibration and Fatigue Resistance

Stainless steel corrugated hoses effectively absorb vibrations and pressure fluctuations from equipment, reducing impact on piping systems and extending the service life of equipment and pipelines. They are particularly suitable for operating environments with mechanical vibrations, such as those found in automobiles and machinery.

Easy Installation

Due to their flexible design, stainless steel corrugated hoses can be easily bent and installed, adapting to various spatial installation requirements. Furthermore, its compact structure requires minimal fixing and support devices, making installation more convenient.

3. Wide Applications of Stainless Steel Corrugated Hoses

Due to the multiple advantages of stainless steel corrugated hoses, they are widely used in various industries. Some major applications are listed below:

Chemical Industry: Chemical production processes often involve the transportation of high-temperature, high-pressure, and corrosive gases or liquids. The high-temperature resistance, corrosion resistance, and pressure resistance of stainless steel corrugated hoses make them an important piping connection tool in chemical equipment. They are used to transport chemicals, liquids, or gases, ensuring the safe operation of equipment.

Oil and Gas Industry: In the refining, transportation, and storage of oil and natural gas, stainless steel corrugated hoses connect pipeline systems and transported media. Due to their corrosion resistance, stainless steel corrugated hoses can withstand environments containing corrosive components such as hydrogen sulfide and chlorides, preventing pipeline leaks or damage.

Aerospace Industry: In aerospace equipment, especially engine and fuel systems, materials with high strength and high-temperature resistance are required. Stainless steel corrugated hoses, with their high-temperature resistance and vibration resistance, are widely used in the aerospace field for fuel transportation, hydraulic systems, etc.

Automotive Industry: Automobile engines and exhaust systems are frequently subjected to high temperatures and pressures, making stainless steel corrugated hoses an indispensable component. They are used in exhaust pipes, coolant lines, fuel lines, and other parts to effectively absorb vibrations, improving vehicle stability and safety.

Construction Industry: In construction projects, especially in water supply and drainage systems, stainless steel corrugated hoses are used to connect water pipes, gas pipelines, etc., ensuring the flexibility of the piping system and preventing damage caused by vibration or temperature changes.

4. Maintenance and Care of Stainless Steel Corrugated Hoses

Although stainless steel corrugated hoses are durable and high-performance, regular maintenance is still essential. Key maintenance measures include regularly inspecting the hose surface for cracks, corrosion, etc., ensuring good seals at joints, and promptly cleaning the inside of the hose to prevent the accumulation of impurities. If severe wear, cracks, or leaks are found on the hose surface during use, it should be replaced immediately.

Due to its superior performance, stainless steel corrugated hoses have become an indispensable key component in many industries. They not only provide multiple layers of protection, including high strength, corrosion resistance, and high-temperature resistance, but also can adapt to complex working environments. With the development of technology and the expansion of application fields, stainless steel corrugated hoses will play an increasingly important role in more industries.